Dynamics 365 Business Central - Managing Scrap in Production Orders

In the manufacturing process, scrap can be generated from various sources such as operations in the routing, individual components, or the final product itself. The configuration of scrap management can significantly affect both material and capacity planning. Moreover, if your inventory is valued through the standard costing method, the scrap-related setup can also impact cost roll-up. Since scrap is prevalent in manufacturing, leveraging its functionality could prove advantageous for many companies.

It is worth noting that in Dynamics 365 Business Central (BC), scrap is considered waste and should not be tracked as inventory. Instead, if you plan to reuse the scrap, it should be handled as an additional output such as by-products or reclaimed materials.

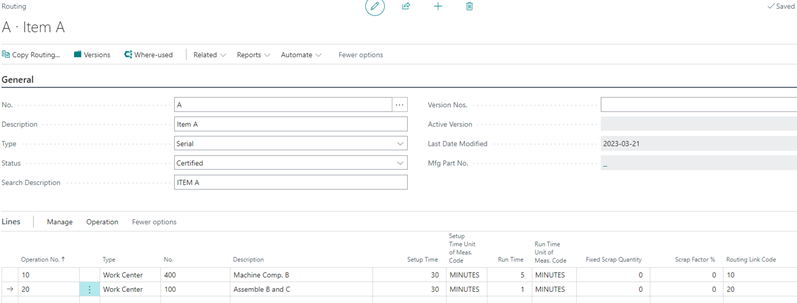

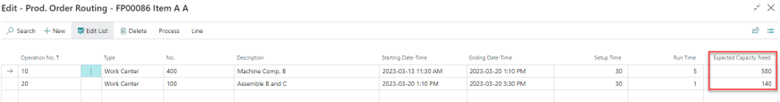

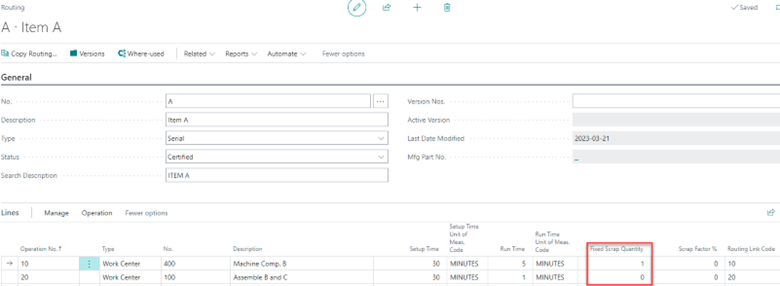

Let's take an example where we produce item A by machining component B and assembling it with component C. The routing with the two operations is set up as follows:

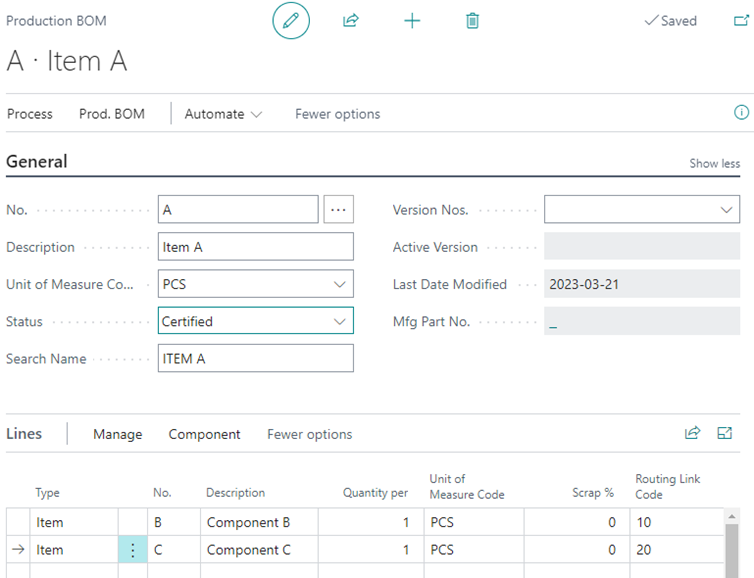

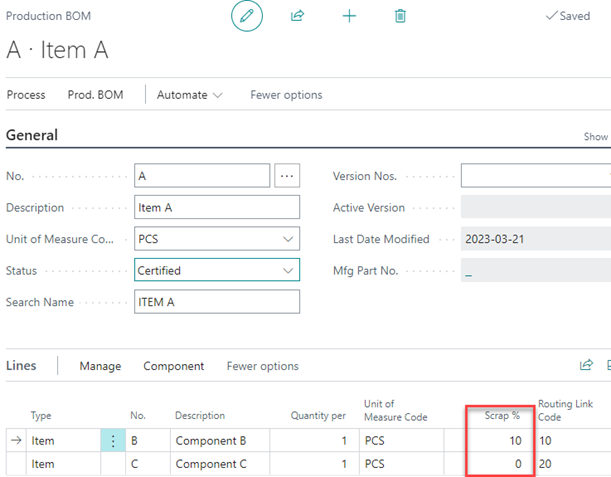

The production BOM includes both components, with routing link codes connecting component B to operation 10 and component C to operation 20.

Now, let's explore the various options related to scrap in BC, using the routing and production BOM mentioned above.

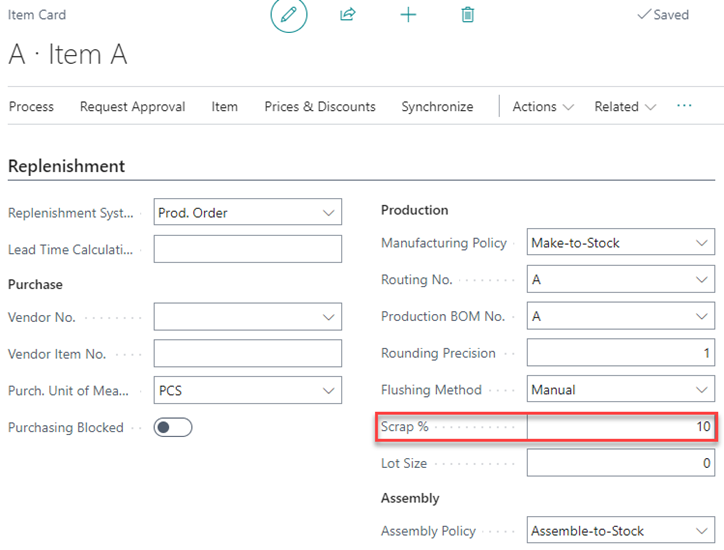

Scenario 1: Item Card setup with Scrap:

The first option to consider is the scrap percentage specified on the item card. This percentage is applied to the finished product and is utilized by BC to adjust the required components and capacity. For example, if you set a 10% scrap on the item card for a production of 100 pcs, BC will generate a demand for 110 pcs of components, and the capacity required will also be based on producing 110 pcs.

To assign the Scrap % in Business Central, navigate to the Replenishment section on the item card:

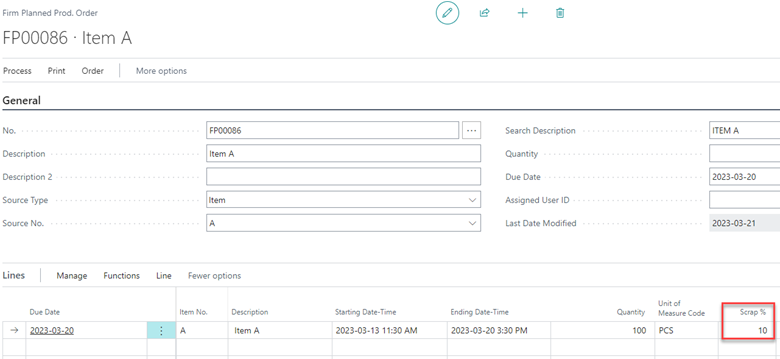

Upon creating a production order, the value of the "Scrap %" field associated with the item is automatically copied to the "Scrap %" field on the corresponding production order line:

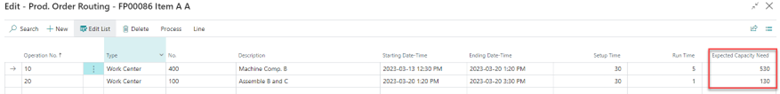

The run time portion of the capacity requirement for each operation is to be incremented by 10%, as if producing 110 pcs instead of 100. This will impact the overall capacity planning for the operations:

Note: The required components have also been increased by 10%.

This feature is useful, for example, when conducting post-production unit inspections (as part of the routing), and an anticipated failure rate is expected.

Scenario 2: Production BOM setup with Scrap:

In addition, you have the option to define a scrap percentage for individual components listed in the production Bill of Materials (BOM). Defining this percentage will increase the required quantity for that particular component, but will not impact the other components or the capacity needs for the operations.

To set this up, simply enter the scrap percentage in the corresponding field provided on the production BOM line:

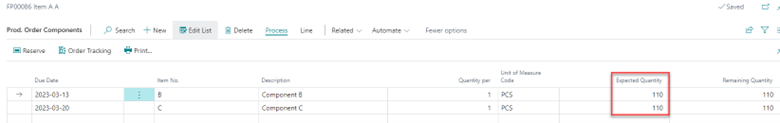

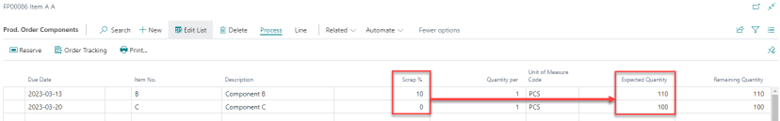

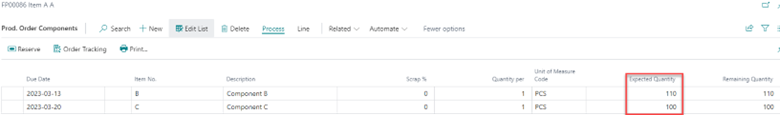

When a production order is generated, the value of the Scrap % field from the corresponding production BOM line is automatically copied over to the Scrap % field of the production order components. As a result, the Expected Quantity for the component is then adjusted to account for the defined scrap percentage.

This does not impact the production order routing.

This feature is useful, for example, in cases where certain components are consumed but not all of them are utilized for any reason, or when only a part of a component is utilized (e.g. 9 ft. of a 10 ft. sheet of steel) and the remainder is scrapped.

Scenario 3: Routing setup with Scrap:

Lastly, it is possible to define scrap in relation to an operation. This is done by utilizing the 'Scrap Factor %' field in the routing. By setting a scrap factor % for an operation, it can be determined whether or not the operation generates scrap. This will increase the required quantities for all components used in the operation, as well as all previous operations, and will also increase the capacity needed for both the operation and its predecessors. To ensure that the correct quantities are calculated, it is important to link the components to the operations using routing link codes.

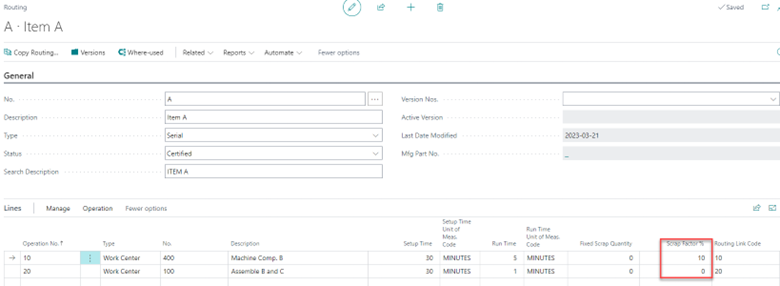

The 'Scrap Factor %' is set up in the routing line:

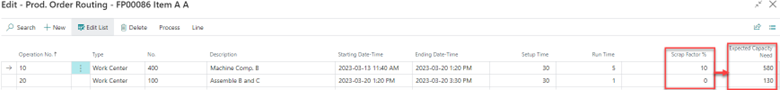

Upon creation of a production order, the Scrap Factor % field value from the routing line is automatically copied to the Scrap Factor % field of the production order routing. Moreover, the capacity requirement for the corresponding operation is adjusted accordingly.

The quantities of related components are correspondingly incremented:

This feature is useful, for example, for operations with a particular anticipated failure rate.

Routing with a fixed quantity of scrap.In Business Central, scrap related to an operation can also be specified as a fixed quantity using the 'Fixed Scrap Quantity' field in the routing. This field functions similarly to the Scrap Factor % field, but is expressed as an absolute quantity rather than a percentage.

To configure this, simply enter the desired value in the Fixed Scrap Quantity field of the routing lines:

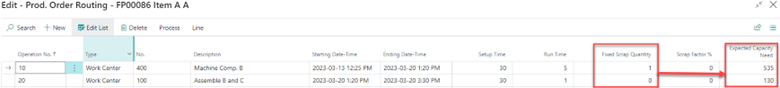

When a production order is generated, the Fixed Scrap Quantity field value from the routing line is automatically copied to the Fixed Scrap Quantity field of the production order routing. Additionally, the capacity requirement for the corresponding operation is adjusted accordingly.

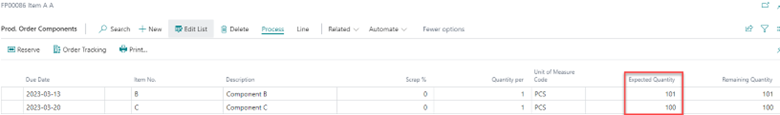

Note: The quantities of related components are respectively incremented:

This is useful in instances such as machine operations that necessitate setup and testing on a few units before beginning the run, as well as conducting destructive testing on a specific quantity as part of the operation.

Posting Consumption with Scrap

In Business Central, it is important to ensure that consumption is recorded accurately based on the exact number of units consumed, including both good and bad units. This will help to maintain an accurate inventory balance and ensure the correct cost is posted against the production order. However, it is worth noting that there is only one consumption quantity field in Business Central, and it does not differentiate between the consumption of components that were used in good parts and those that were scrapped.

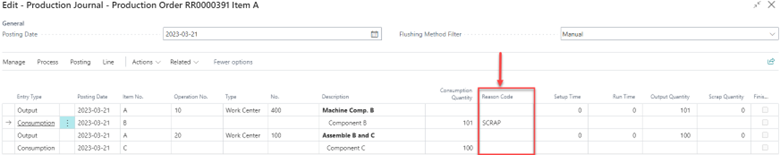

To record why there was more consumption than expected, you can use the 'Reason Code' field. This field is not available by default in the journal, it can be added with the help of an extension. In Business Central, the reason code can be set up against each line rather than just the journal batch, but adding the field to the journal will suffice if needed.

In Business Central, a potential drawback of using reason codes to track scrap is their non-mandatory nature. Additionally, making them mandatory presents a challenge due to the limited field availability to enter the consumed quantity. Constantly mandating their use adds unnecessary overhead during consumption posting. Therefore, an alternative solution to capture scrap reasons effectively would be to use 'Scrap Codes' for outputs, as detailed below.

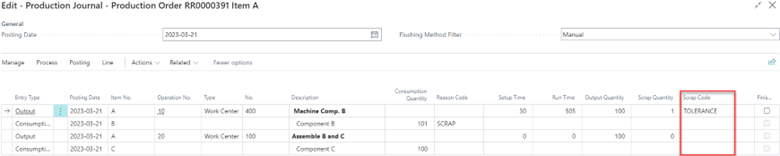

Posting Output with ScrapIn Business Central, when posting operation outputs, there are two fields to consider: "Output Quantity" and "Scrap Quantity". It's essential to differentiate between the quantity of good parts and scrap parts during the posting process. The "Output Quantity" represents the quantity of goods that will be added to the stock (if it's the last operation) and will bear all the production costs. On the other hand, the "Scrap Quantity" will only be recorded against the operation on the capacity ledger entries. Additionally, there is a "Scrap Code" field available for the output, which enables you to select a code to record the reason for the scrap.

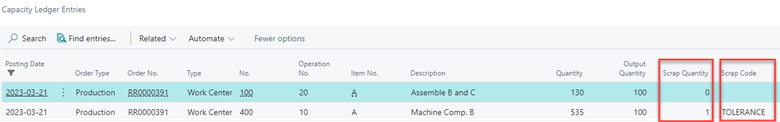

When the journal is posted, both the Scrap Quantity and Scrap Codes are recorded in the Capacity Ledger Entries, which can then be utilized to analyze the reasons for scrap.

When utilizing backflushing for component allocation in Business Central, the system calculates the quantity of components used by factoring in both the output quantity and the scrap quantity. To ensure accurate record-keeping, it is imperative to input the scrap quantities when entering backflushing information.

Before implementing or altering the setup for a large number of items, it is wise to create sample items and simulate their behavior to better understand the potential outcomes. This approach applies to any process, and it can help avoid costly mistakes or complications.