Mastering Manufacturing with Business Central: Adjusting Schedules and Capacity Optimization

Introduction

In manufacturing, the ability to dynamically adjust production schedules is crucial for maintaining efficiency and meeting demand. Microsoft Dynamics 365 Business Central enables manufacturers to optimize capacity by adjusting production schedules in real time, ensuring that resources are utilized effectively and bottlenecks are minimized.

In this blog, we will explore how to adjust production schedules, optimize work center capacity, and leverage Business Central's built-in tools for maximum efficiency.

The Importance of Real-Time Scheduling Adjustments

One of the standout features of Business Central's capacity planning module is the ability to adjust production orders in real time. Whether it's shifting production due to machine maintenance or redistributing work to accommodate a new order, these changes can be made instantly without disrupting the entire production line.

Business Central allows manufacturers to modify firm planned and released production orders to adjust their start and end dates, redistribute workloads, and optimize capacity usage. This is particularly important when handling unexpected delays or new high-priority jobs.

How to Adjust Production Orders in Business Central

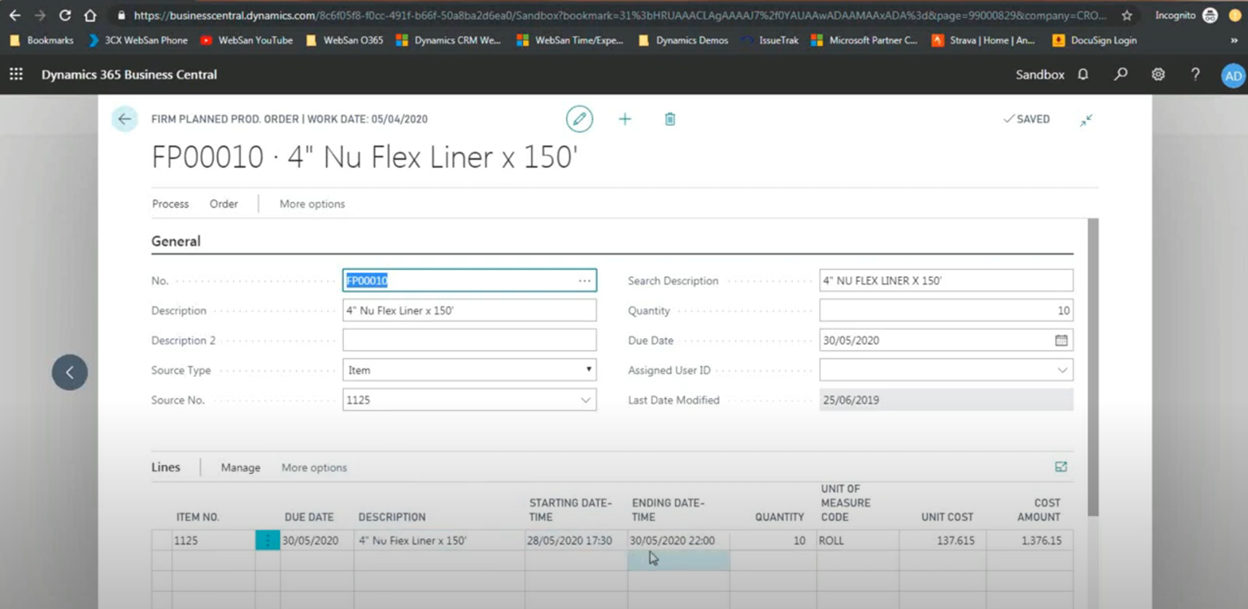

Adjusting production orders in Business Central begins at the Firm Planned Production Order screen. From here, users can modify the Start Date and End Date of the order, shifting it forward or backward as necessary.

In the demonstration, a firm planned production order is adjusted, and the system instantly recalculates the capacity load and redistributes it across the shop floor.

Business Central ensures that any adjustment is immediately reflected in the Work Center Load Report, allowing manufacturers to see the impact of these changes on overall capacity. This visibility helps prevent overloading work centers and identifies available capacity that can be leveraged for new orders.

Optimizing Work Center Capacity

Adjustments are not limited to just production orders. Business Central also allows you to optimize individual Work Centers by redistributing workloads or moving tasks to different centers with available capacity. This is particularly valuable for manufacturers running multiple shifts or managing seasonal demand fluctuations.

In the video demonstration, adjustments are made to the QA Work Center, redistributing some of the load to other available machine centers.

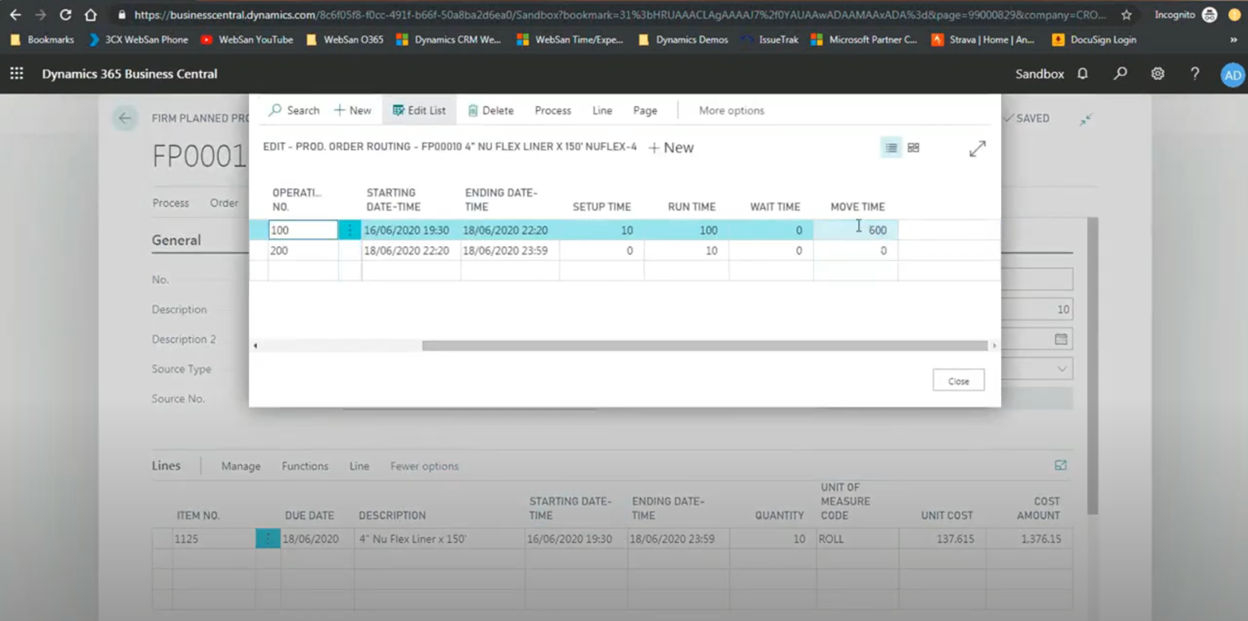

Additionally, users can configure Move Time and Wait Time to better account for delays between work centers. For example, if QA is running behind, a manufacturer can adjust the wait time to prevent idle machine centers downstream. These adjustments ensure that every resource is being used effectively, reducing idle time and increasing throughput.

Managing Buffer Times and Wait Times

Business Central supports the configuration of Buffer Times and Wait Times to help optimize production flow. Buffer time refers to the gap between production steps to account for unexpected delays or preparation, while wait time is the idle period before the next process begins.

In the demonstration, these settings are configured directly within the Routing Setup, which determines how each step in the production process is scheduled.

Adjusting these times allows manufacturers to:

- Smooth out production flows between work centers.

- Prevent bottlenecks during peak production periods.

- Increase overall throughput by minimizing idle time.

Using the Capacity Load Report for Scheduling Adjustments

One of the most powerful tools for capacity optimization in Business Central is the Capacity Load Report. This report provides a clear view of current work center loads, helping manufacturers identify bottlenecks and underutilized resources.

In the webinar, the Capacity Load Report is used to visualize adjustments made to production orders. When dates or routing configurations are changed, the report instantly updates to reflect new capacity loads.

The report is especially useful for planning future production, as it provides insight into which work centers are overloaded and where spare capacity exists. This allows manufacturers to make proactive adjustments to prevent delays and optimize output.

Real-World Example: On-the-Fly Scheduling Adjustments

In a real-world scenario, manufacturers often need to make quick decisions to accommodate unexpected changes. For example, if a key machine breaks down, production must be shifted to another work center without disrupting the overall schedule.

In Business Central, this can be done swiftly by accessing the Work Center Load screen, identifying available capacity, and reassigning tasks as needed. These changes are reflected immediately, allowing for seamless transition without halting production.

In the demonstration, the speaker shows how a firm planned production order is moved from one date to another, instantly adjusting the load across work centers.

Watch the Full Webinar

If you want to see this in action, watch our full webinar:

Microsoft Dynamics 365 Business Central Manufacturing Series Part V: Capacity Planning

Contact Us to Learn More

Ready to optimize your manufacturing operations with Business Central? Contact WebSan Solutions to learn how we can help you implement capacity planning and streamline your production processes.