Mastering Manufacturing with Business Central - Demand Forecasting in Business Central: How Data-Driven Planning Improves Inventory Management

Accurate demand forecasting is crucial for manufacturers and distributors to maintain optimal inventory levels, prevent stock shortages, and avoid overstocking. Without a structured forecasting process, businesses risk misaligning inventory with actual demand, leading to inefficiencies in production and order fulfillment.

In Microsoft Dynamics 365 Business Central, demand forecasting is based on historical sales data, sales orders, and planning worksheets. The system allows businesses to enter forecasted demand manually and use historical data to generate demand estimates.

This blog will cover how demand forecasting works in Business Central, its role in production and inventory planning, and best practices for improving forecasting accuracy.

How Demand Forecasting Works in Business Central

Business Central helps manufacturers and distributors forecast demand by tracking historical sales, current sales orders, and expected trends. The system does not automate forecasts using AI but provides structured tools for manually entering and adjusting demand projections.

Types of Demand in Business Central:

- Independent Demand: This comes from sales orders or manually entered forecasts, which drive finished goods production.

- Dependent Demand: This is calculated based on the Bill of Materials (BOM) and represents the raw materials required for production.

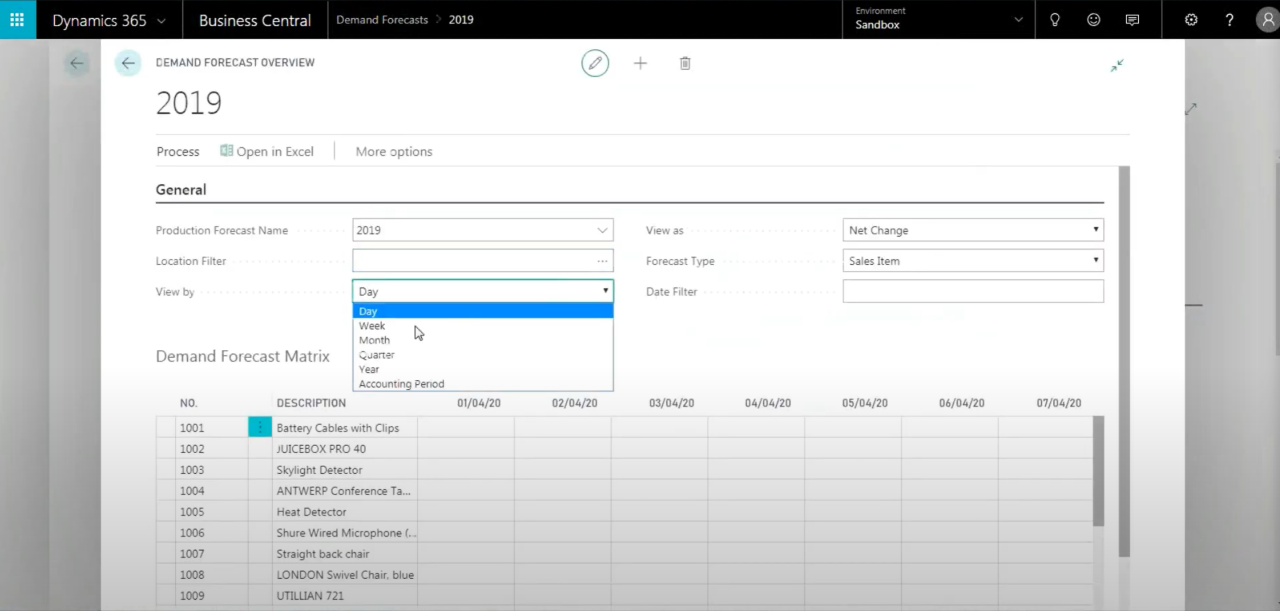

Steps to Enter a Demand Forecast in Business Central:

- Navigate to the Demand Forecast Page in Business Central.

- Select the forecast period (daily, weekly, monthly, quarterly).

- Manually enter expected demand per item based on sales trends or business knowledge.

- Use historical data from previous sales periods to refine forecasts.

By utilizing this structured approach, businesses can anticipate seasonal fluctuations and adjust inventory planning accordingly.

Forecasting by Location: Managing Demand Across Multiple Warehouses

For companies with multiple warehouses or store locations, Business Central allows forecasting at a regional level. This ensures that businesses can manage stock efficiently across different locations.

How Business Central Handles Location-Based Forecasting:

- Users can enter demand forecasts for each warehouse separately.

- Forecasts can be adjusted based on regional buying patterns and expected order volumes.

- Businesses can transfer inventory between warehouses based on demand fluctuations.

This feature helps prevent stock shortages in high-demand regions while avoiding excess inventory buildup in low-demand areas.

Net Change Calculations: Keeping Forecasts Up to Date

In Business Central, demand forecasts are not static—the system updates planning recommendations based on real-time sales activity and order adjustments.

How Net Change Forecasting Works:

- When new sales orders are created, Business Central adjusts forecasts accordingly.

- If orders are cancelled or rescheduled, demand calculations are updated.

- Inventory planners can review updated planning worksheets to adjust stock levels.

This functionality ensures that businesses can react quickly to demand shifts, reducing the risk of overproduction or stockouts.

Using Forecasts to Improve Inventory Planning

Demand forecasting in Business Central directly impacts inventory planning and procurement. Once demand forecasts are entered, the system integrates them into planning worksheets to recommend stock replenishment actions.

How Forecasting Integrates with Inventory Planning:

- The system calculates future inventory needs based on demand forecasts.

- Business Central generates replenishment recommendations to maintain optimal stock levels.

- Planners can adjust forecasts before placing purchase or production orders.

By aligning demand forecasts with inventory planning, businesses can reduce carrying costs, improve order fulfillment, and optimize supplier relationships.

Best Practices for Demand Forecasting in Business Central

To improve forecasting accuracy, businesses should follow these best practices:

- Analyze historical sales data: Look at previous demand trends to make data-backed forecasts.

- Update forecasts regularly: Adjust demand predictions based on current market conditions and real-time sales trends.

- Use location-based forecasting: Ensure that each warehouse has an accurate forecast to prevent stock imbalances.

- Monitor planning worksheets frequently: Review the system's replenishment recommendations to adjust stock levels as needed.

By refining forecasting processes, businesses can prevent costly inventory mistakes and improve supply chain efficiency.

How Demand Forecasting Impacts Business Performance

When businesses implement structured demand forecasting in Business Central, they see improvements in inventory efficiency, procurement planning, and overall cash flow management.

Key Benefits of Demand Forecasting:

- Prevents Stockouts & Overstocking: Ensures that inventory levels are aligned with actual demand.

- Reduces Holding Costs: Avoids excessive stock accumulation that ties up cash flow.

- Improves Order Fulfillment: Ensures that customers receive their products on time, without delays.

- Enhances Supplier Coordination: Helps businesses plan smarter purchase orders, reducing last-minute rush orders.

Accurate demand forecasting allows businesses to make informed decisions, minimize risks, and maximize profitability.

Final Thoughts & Watch the Webinar

Forecasting in Business Central relies on structured data entry, historical trends, and planning worksheets to help businesses maintain optimal inventory levels. While it does not use AI-powered automation, the system's forecasting tools allow businesses to make data-driven inventory decisions and adjust forecasts in real-time based on sales fluctuations.

By leveraging Business Central's forecasting tools, businesses can:

- Predict demand more accurately based on past trends.

- Optimize inventory by adjusting forecasts at the warehouse level.

- Reduce stockouts and excess inventory through proactive planning.

- Improve supply chain efficiency by aligning demand with procurement and production schedules.

Watch the full webinar here:

Microsoft Dynamics 365 Business Central Forecasting & Planning Webinar

For expert guidance on implementing demand forecasting in Business Central, contact WebSan Solutions for a personalized consultation.