Mastering Manufacturing in Business Central - Optimizing Inventory Planning in Business Central: Choosing the Right Reordering Policies

For manufacturers and distributors, inventory planning is a delicate balance. Holding too much stock ties up capital and increases storage costs, while too little stock results in missed sales and production delays. Microsoft Dynamics 365 Business Central offers multiple reordering policies that help businesses optimize their inventory replenishment strategies.

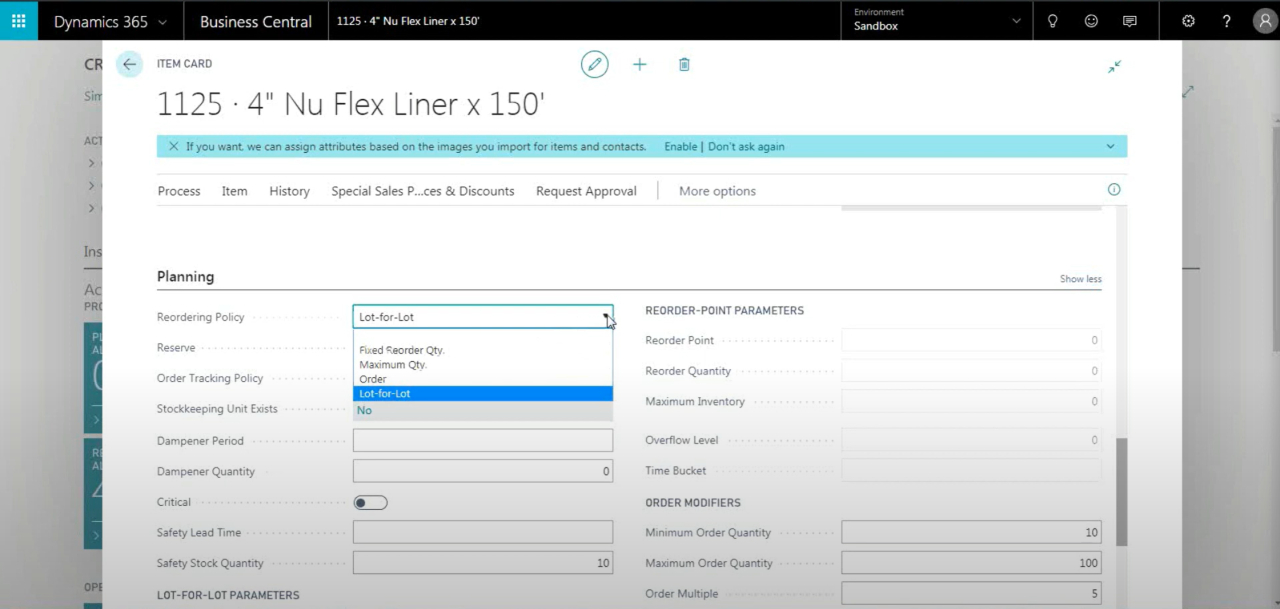

Understanding how to use Fixed Order Quantity, Maximum Order Quantity, Lot-for-Lot, and Order policies correctly can reduce excess inventory, prevent stockouts, and improve supply chain efficiency.

In this blog, we'll explore Business Central's reordering policies, when to use each one, and best practices for implementing them in your business.

What Are Reordering Policies in Business Central?

Reordering policies in Business Central determine how the system calculates replenishment quantities when stock levels reach a reorder point. The right policy depends on factors like demand variability, supplier lead times, and storage capacity.

Types of Reordering Policies:

- Fixed Order Quantity: Orders a predefined quantity whenever stock reaches the reorder point.

- Maximum Order Quantity: Prevents stock from exceeding a set level.

- Lot-for-Lot: Aggregates demand over a specific period to create an optimized replenishment order.

- Order Policy: Directly links procurement or production to customer orders.

Choosing the right policy ensures efficient stock control and prevents unnecessary ordering or shortages.

Fixed Order Quantity: When Consistency is Key

The Fixed Order Quantity policy instructs Business Central to always order the same quantity whenever stock reaches the reorder point. This method is best for products with consistent demand or where ordering in bulk reduces costs.

How It Works:

- The system monitors stock levels and identifies when they fall below the reorder point.

- A purchase order or production order is triggered for the fixed quantity.

- The process repeats each time the reorder point is reached.

Best Use Cases:

- Items with steady demand (e.g., screws, bolts).

- Products with economies of scale when purchased in bulk.

- Supplier agreements requiring minimum order quantities.

Fixed Order Quantity ensures reliable stock levels but may result in overstocking if demand fluctuates.

Maximum Order Quantity: Preventing Overstock

The Maximum Order Quantity policy helps businesses control excess inventory by ensuring stock never exceeds a predefined maximum level.

How It Works:

- When stock reaches the reorder point, the system calculates the required quantity but caps it at the maximum level.

- If demand is higher than the max quantity, multiple smaller orders may be generated instead of one large order.

Best Use Cases:

- Businesses with limited warehouse space.

- Products with short shelf life (e.g., perishable goods).

- Companies looking to reduce holding costs.

This policy prevents excessive stock accumulation, reducing storage costs and potential inventory obsolescence.

Lot-for-Lot: Aligning Orders with Demand

Lot-for-Lot is one of the most flexible reordering policies in Business Central. Instead of using a fixed order quantity, this policy aggregates demand over a predefined period (e.g., a month) and creates an optimized replenishment order.

How It Works:

- The system accumulates all demand for a product over a set period (e.g., one month).

- A single purchase or production order is generated to cover that demand.

- The next order is placed at the end of the planning period.

Best Use Cases:

- Products with fluctuating demand.

- Businesses looking to minimize order frequency while maintaining stock availability.

- Items with long supplier lead times, requiring consolidated ordering.

Lot-for-Lot reduces frequent ordering, making it ideal for businesses that want to optimize procurement costs and reduce excess stock.

Order Policy: Ideal for Make-to-Order Businesses

Unlike other reordering policies that focus on stock replenishment, the Order policy directly links production or purchasing to individual customer orders.

How It Works:

- When a sales order is created, the system immediately triggers a corresponding purchase or production order.

- There is no excess inventory, as each order is fulfilled on demand.

Best Use Cases:

- Make-to-Order manufacturers producing custom goods.

- High-value, low-volume products (e.g., specialized machinery).

- Businesses that want to minimize inventory carrying costs.

The Order policy is perfect for businesses that prioritize customization and lean inventory management, though it requires accurate lead time forecasting to prevent delays.

Choosing the Right Reordering Policy: Key Considerations

Selecting the right reordering policy depends on your business needs and inventory strategy.

| Policy | Best For | Potential Drawbacks |

| Fixed Order Quantity | Predictable demand, bulk discounts | May lead to overstocking |

| Maximum Order Quantity | Space constraints, short shelf life | Can result in frequent orders |

| Lot-for-Lot | Fluctuating demand, cost efficiency | Requires careful demand forecasting |

| Order | Make-to-Order businesses | Longer lead times if not managed properly |

By carefully evaluating demand patterns, supplier constraints, and storage capacity, businesses can choose the best policy for optimized stock control.

Final Thoughts & Watch the Webinar

Inventory planning is a critical component of supply chain management, and choosing the right reordering policy in Business Central can maximize efficiency, reduce costs, and improve service levels.

By leveraging Business Central's reordering policies, businesses can:

- Reduce excess inventory and carrying costs.

- Prevent stockouts and supply chain disruptions.

- Align inventory levels with real demand.

Watch the full webinar here:

Microsoft Dynamics 365 Business Central Forecasting & Planning Webinar

For expert guidance on implementing inventory planning strategies in Business Central, contact WebSan Solutions to get started today.