Mastering Manufacturing with Business Central: Configuring Reordering Policies

In our last blog, we explored the differences between Make to Order (MTO) and Make to Stock (MTS) in Microsoft Dynamics 365 Business Central. Now, let's dive deeper into the mechanics of how Business Central plans production and purchasing using Reordering Policies.

This post walks through each policy type, how to set them up, and how they affect your supply planning in both Make to Order and Make to Stock environments.

Reference video:

Make to Order vs. Make to Stock in Business Central

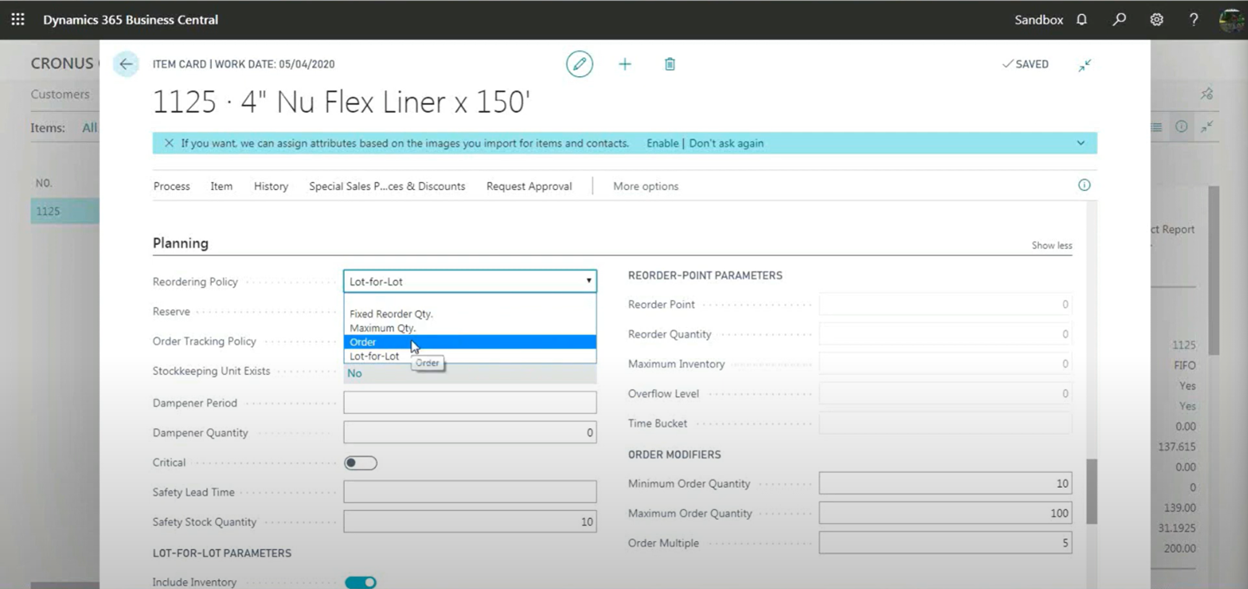

Where to Set Reordering Policies

Reordering policies are configured on the Item Card under the Planning tab.

- Navigate to the item (e.g., Item 1125 used in the video).

- Go to the Planning section.

- Look for the Reordering Policy field.

The Four Reordering Policies in Business Central

Let's break down each policy type and how it's used:

1. Order (Make to Order)

Used in Make to Order scenarios. Business Central creates a planned production or purchase order only when a sales order exists—nothing else triggers it.

- Inventory is reserved for the sales order.

- No forecasting, no safety stock, no batch production.

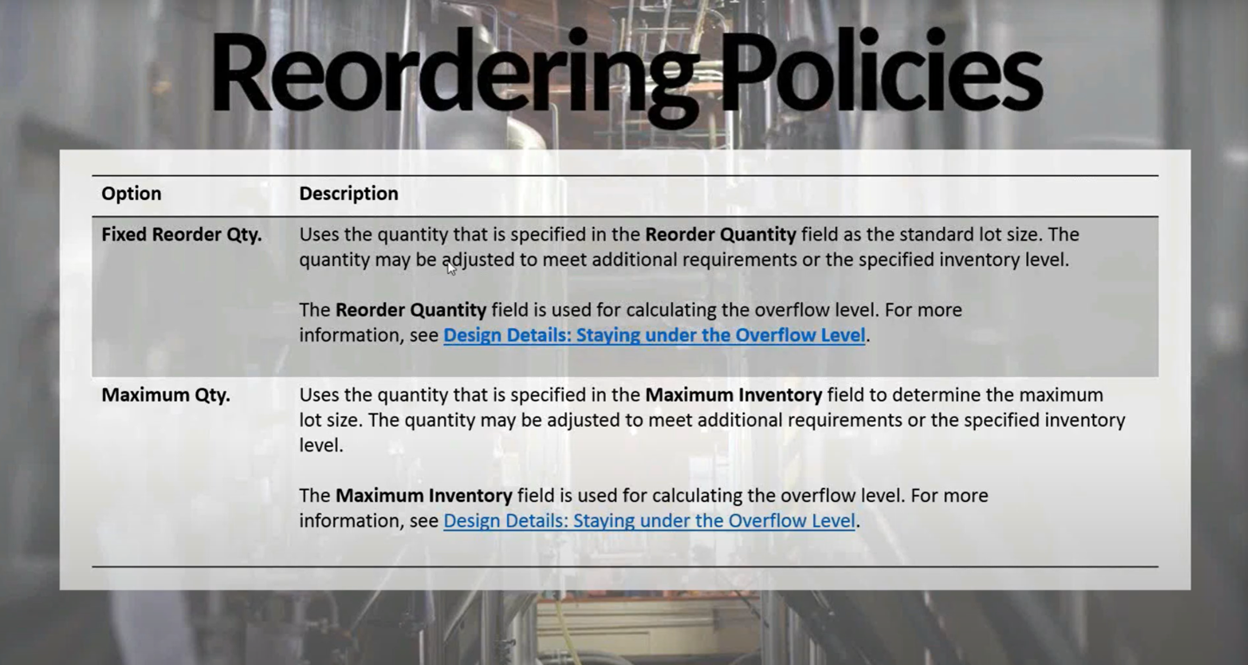

2. Fixed Reorder Quantity (Make to Stock)

Used when you always want to order or produce a fixed amount, regardless of demand.

- Example: If reorder quantity is set to 1,000, BC will always create a planned order for 1,000—even if you only need 500.

- Useful for bulk production or bulk purchasing.

3. Maximum Quantity (Make to Stock)

Plans inventory replenishment up to a maximum level.

- Example: If your max is 2,000 and you have 500 on hand, the system will plan for 1,500.

- Best used when you want to cap stock levels and avoid overproduction.

4. Lot-for-Lot (Make to Stock with Flexibility)

The most flexible Make to Stock method. Plans supply to meet total demand within a planning period (day, week, month).

- Gathers requirements (sales orders, forecasts, safety stock) over a defined time window and creates one supply order.

- If your planning period is 1 week, BC will group all weekly demand into a single planned order.

Bonus Settings to Know

Safety Stock

Defines the minimum quantity you always want on hand.

Blank (No Planning)

If no reordering policy is selected, the system won't plan anything for the item.

Visual Summary: When to Use Each Policy

| Reordering Policy | Best For | Make to Order / Stock | Behaviour |

| Order | Custom or high-cost items | Make to Order | Plans per sales order |

| Fixed Reorder Quantity | Bulk manufacturing | Make to Stock | Always orders fixed amount |

| Maximum Quantity | Capped inventory | Make to Stock | Orders to reach max level |

| Lot-for-Lot | Dynamic demand planning | Make to Stock | Plans by grouped demand in period |

What's Next in the Series?

In Blog 3, we'll jump into how Business Central's MRP engine behaves when using Make to Order. You'll see:

- How sales orders trigger planned production

- How inventory is reserved automatically

- The power of "Order Tracking Policy" to trace demand to supply

Need Help Setting This Up?

Whether you're configuring Business Central for the first time or trying to improve your current planning strategy, our team of manufacturing experts is here to help.

Contact WebSan Solutions today to book a free consultation.