Mastering Manufacturing with Business Central: Mastering Components: Items, BOM, and Routings in Business Central

Building the Foundation of Manufacturing

Behind every great manufacturing operation lies a solid foundation of well-structured components, bills of material (BOM), and routings. In Microsoft Dynamics 365 Business Central, these elements work together to ensure every production process is efficient and cost-effective.

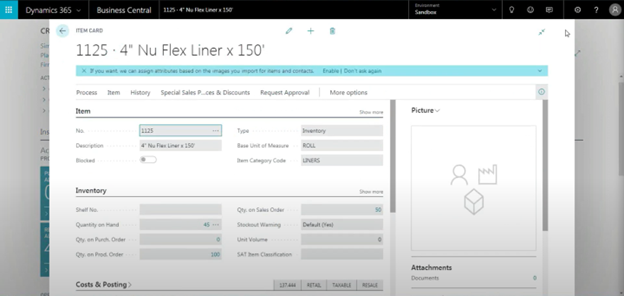

Items and Their Role in Manufacturing

The item master in Business Central is your starting point for defining how each component behaves in the manufacturing process. Key settings include:

- Replenishment Type: Distinguish between buy, make-to-stock, or make-to-order items.

- Flushing Methods: Choose between manual, forward, or backward flushing to determine how and when components are consumed.

Understanding these options ensures your inventory aligns with production needs.

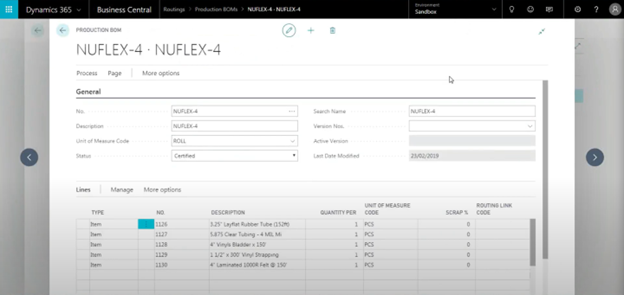

Bills of Material (BOM): The Recipe for Success

A BOM outlines the ingredients required to produce a finished product. Whether you're working with single-level or multi-level BOMs, Business Central provides flexibility and precision. Features include:

- Quantity per finished good.

- Routing link codes to synchronize components with operations.

- Scrap percentages for accurate planning.

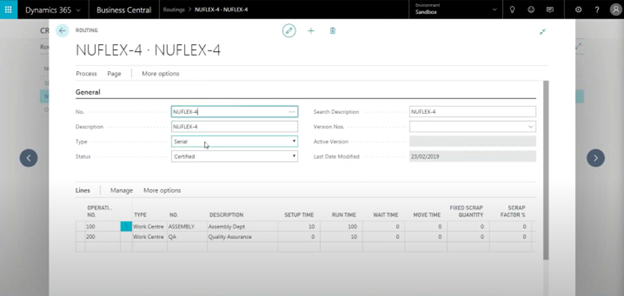

Routings: The Path to Production

Routings define the steps needed to transform raw materials into finished goods. Each routing step specifies:

- The operation sequence.

- Work centers or machines involved.

- Time and cost per operation.

By aligning routings with BOMs, you create a seamless flow from start to finish.

Take Action:

Watch the full webinar to see how BOMs and routings integrate seamlessly in Business Central.