Mastering Manufacturing with Business Central: Introduction to Manufacturing in Business Central

Welcome to the Manufacturing Revolution

Manufacturing is the engine of the global economy, and in today's competitive landscape, businesses must adapt quickly to changing demands while maintaining operational efficiency. For small to medium-sized manufacturers, this can be a daunting task. However, Microsoft Dynamics 365 Business Central's manufacturing module offers a solution that combines comprehensive functionality with user-friendly design.

This blog is the first in our "Mastering Manufacturing with Business Central" series, where we'll take you step-by-step through everything you need to know to become a manufacturing expert in Business Central. Today, we're starting with an overview of the module, setting the stage for the deeper dives ahead.

What Makes the Business Central Manufacturing Module Powerful?

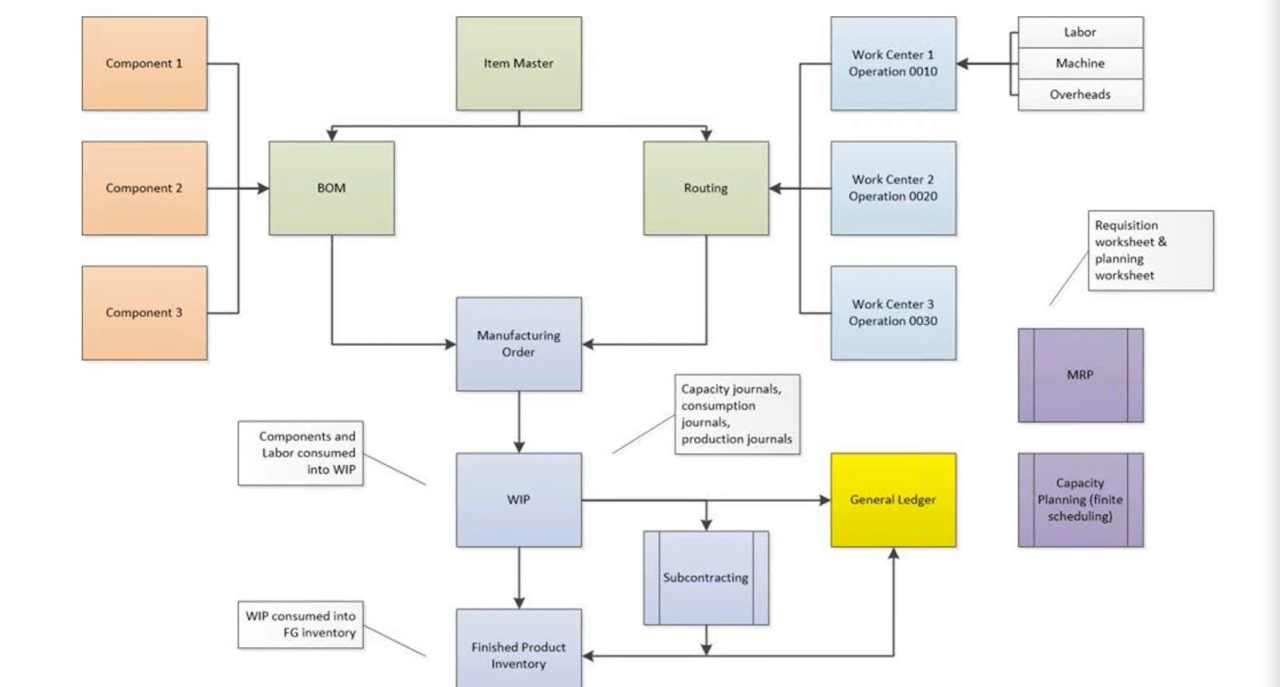

Business Central's manufacturing module isn't just software; it's a toolkit for transforming your operations. Here are some of the core components that make it stand out:

- Bills of Material (BOM): A BOM is essentially a recipe for your product. It lists all the components required, from raw materials to subassemblies, and defines the quantities needed for production.

- Routings: These define the step-by-step process of manufacturing a product. Each routing specifies the operations, tools, and resources required to move from raw material to finished goods.

- Work Centers: These represent the physical or logical resources—labour, machinery, or subcontractors—used in production.

- Production Orders: These orders orchestrate the entire process, guiding your team and system through the production lifecycle.

Unlike standalone tools, Business Central integrates all these components into a unified system, ensuring seamless communication between planning, production, and accounting teams.

The Manufacturing Workflow in Business Central

At a high level, manufacturing in Business Central follows a logical flow that mirrors real-world processes:

1. Define Your Products: Every manufacturing operation starts with items. Business Central's item master data lets you define the characteristics of your products, including:

- Base Unit of Measure: Whether you produce items in pieces, kilograms, or meters, you can set a base measure that fits your needs.

- Costing Methods: Select from FIFO, standard, or average costing to track your expenses accurately.

- Planning Parameters: Include safety stock levels, reorder points, and lead times to optimize your supply chain.

BOM: Specify the components needed for each product. For example, a bicycle's BOM might include wheels, a frame, and a chain.

Routing: Define the operations required to assemble the bicycle, from welding the frame to painting and quality assurance.

3. Create Production Orders:

Generate orders based on demand, forecasts, or inventory needs.

Use the system's built-in Material Requirements Planning (MRP) to automate order creation.

4. Manage the Production Process:

Track progress through work centers.

Record labour and material usage with tools like the Consumption Journal and Capacity Journal.

5. Deliver the Finished Product: Once production is complete, finished goods are moved into inventory, ready for sale or distribution.

Why Small and Medium Manufacturers Love Business Central

Business Central isn't just for large enterprises. It's designed with small and medium manufacturers in mind, offering:

- Scalability: Start simple and add complexity as your business grows.

- Customization: Tailor workflows, dashboards, and reports to your unique needs.

- Cloud Integration: Access your system from anywhere, ensuring business continuity even when teams are remote.

Practical Example: The Cake Analogy

To simplify the concept, imagine you're running a bakery. Your product is a cake, and your manufacturing process looks like this:

- BOM: The recipe: listing flour, eggs, sugar, and icing as components.

- Routing: The steps: mixing, baking, cooling, and decorating.

- Work Centers: The oven (machinery), decorators (labour), and cooling racks (subcontractors).

- Production Order: A guide for making 10 cakes based on a customer order.

Business Central helps you track every step, ensuring you never miss an ingredient or a step in the process.

How Business Central Compares to Traditional ERP Systems

Many legacy ERP systems require separate tools or customizations for manufacturing. Business Central integrates everything out of the box, saving time and reducing errors. For example:

- Integration with Financials: Manufacturing transactions automatically update the general ledger, providing real-time cost tracking.

- Power BI Reporting: Analyze production performance and costs with visual, dynamic dashboards.

- Automated MRP: Unlike manual planning tools, MRP in Business Central considers lead times, safety stock, and demand in one go.

Looking Ahead

This blog just scratches the surface. In the upcoming posts, we'll take a closer look at:

- Master data management, including item setup and BOMs.

- Production orders and flushing methods.

- MRP and advanced planning tools.

- Costing and general ledger integration.

By the end of this series, you'll have a comprehensive understanding of how to manage manufacturing in Business Central—and you'll see why it's one of the most powerful tools for growing manufacturers.