Mastering Manufacturing with Business Central: Setting the Stage – Master Data in Business Central

Laying the Foundation for Manufacturing Success

When it comes to manufacturing, master data is the blueprint that drives your operations. Accurate and complete master data isn't just a technical requirement; it's the difference between seamless production and costly errors. From defining items and components to creating bills of material (BOMs) and routings, master data sets the stage for every production order.

In this second installment of our "Mastering Manufacturing with Business Central" series, we dive deep into how to set up and manage master data in Dynamics 365 Business Central.

What Is Master Data in Manufacturing?

Master data encompasses all the foundational information that supports manufacturing processes, including:

- Item Master Data: Details about finished goods, sub-assemblies, and raw materials.

- Bills of Material (BOMs): The components and quantities required to produce a product.

- Routings: The steps and resources needed to transform components into finished goods.

Business Central integrates these elements into a cohesive system, ensuring that your manufacturing operations run smoothly.

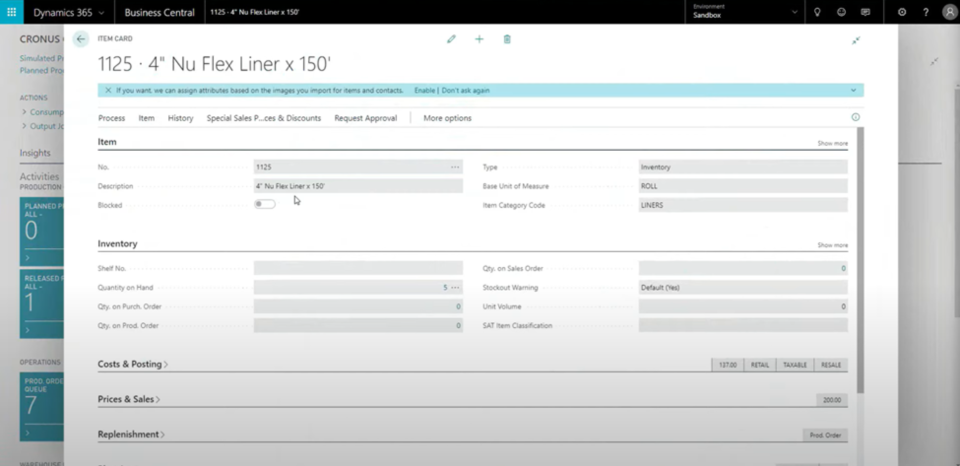

Step 1: Item Master Setup

The Item Master is where it all begins. Every product, raw material, or subassembly is defined here with attributes that guide production and inventory management. Key fields to focus on include:

- Base Unit of Measure

- Defines how items are quantified (e.g., pieces, kilograms, or rolls).

- Example: A roll of fabric might have a base unit of measure set to "roll," with 150 feet per roll.

- Inventory and Costing Details

- Select a costing method: FIFO, standard, or average. For most manufacturers, FIFO or standard is recommended to track costs accurately.

- Define inventory levels, safety stock, and reorder points.

- Flushing Methods

- Backflushing: Automatically consumes components and labour when production is reported.

- Manual: Requires explicit reporting of component and labour usage.

- Planning Parameters

- Set minimum order quantities, lead times, and lot sizes to streamline procurement and production.

Step 2: Bills of Material (BOM)

A BOM is the recipe for your product, listing all the ingredients (components) required to create a finished good. In Business Central, you can create simple or complex BOMs depending on your needs.

Example: Producing a Custom Bicycle

- Components: Frame, wheels, chain, brakes, and handlebars.

- Quantities: 1 frame, 2 wheels, 1 chain, etc.

- Options: Add scrap percentages or substitute components for flexibility.

Practical Tip: Ensure BOMs are accurate before production. Even a small error, like a missing component, can disrupt the manufacturing process.

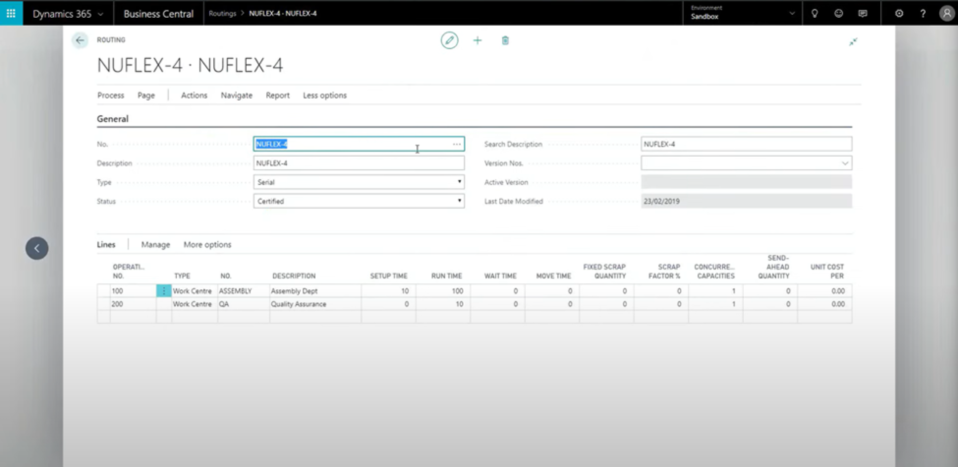

Step 3: Routing Setup

Routings define the sequence of operations needed to produce a product. Each operation is linked to a work center, detailing:

- Setup and Run Times: Specify the time required for each operation.

- Work Centers: Assign operations to departments or machines.

- Parallel Operations: For advanced setups, Business Central allows operations to run simultaneously.

Example: Cake Manufacturing Routing

- Mixing: Combine ingredients (Work Center: Mixer).

- Baking: Place in oven (Work Center: Oven).

- Decorating: Apply icing and toppings (Work Center: Decorator).

Why Master Data Matters

Accurate master data ensures:

- Efficient Production: Reduce downtime caused by missing or incorrect information.

- Cost Control: Track real-time costs against estimates to identify variances.

- Scalability: Build a robust foundation for future growth, enabling more complex processes over time.

Looking Ahead

Master data is just the beginning. In the next blog, we'll explore how to use this data to create and manage production orders, the heartbeat of your manufacturing operations.

Want to dive deeper into how Business Central can revolutionize your manufacturing processes? Watch our detailed walkthrough in the YouTube video, Microsoft Dynamics 365 Business Central Manufacturing Series Part I: Manufacturing Concepts. Gain more insights, see real examples, and learn how to implement these concepts in your business.