Mastering Manufacturing with Business Central: Streamlining Work Centers and Capacity Planning

Optimizing Resources for Maximum Efficiency

One of the most overlooked aspects of manufacturing is the effective use of resources. Whether it's machines, labour, or materials, inefficiencies can cost both time and money. In Microsoft Dynamics 365 Business Central, work centers and capacity planning tools help manufacturers allocate resources effectively, maximize output, and avoid bottlenecks.

Understanding Work Centers: Building Blocks of Efficiency

At the heart of capacity planning are work centers, which define the location, resources, and costs associated with each step in your production process. Business Central organizes work centers into a hierarchical structure to suit varying levels of complexity:

- Individual Machines or Resources: These are the smallest units, representing specific people, equipment, or tools.

- Work Centers: A group of machines or resources that perform similar tasks, such as an assembly or QA department.

- Work Center Groups: Collections of work centers, such as all milling machines in a factory.

This hierarchy enables you to drill down to specific machines or scale up to see resource availability across entire groups. For example, if you have three milling machines with different capacities, you can evaluate them individually or as part of a milling department.

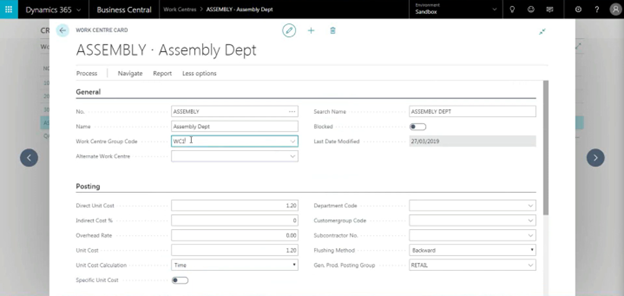

Key Features of Work Centers

Each work center in Business Central offers flexibility in defining how it operates:

- Capacity Settings: Define hours of availability per day or week, adjust for efficiency (e.g., lunch breaks), and set shop calendars to account for holidays or downtime.

- Cost Tracking: Assign direct and indirect costs, such as labour rates and overhead, to calculate accurate production costs.

- Routing Links: Tie work centers to specific routing steps to streamline the flow of components.

These settings allow manufacturers to customize work centers to match their specific production environment, creating a scalable system.

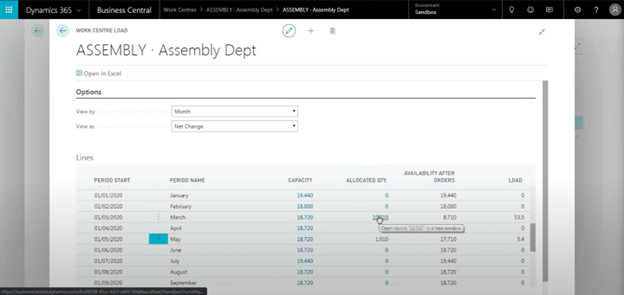

Capacity Planning: Balancing Load and Availability

Business Central goes beyond static scheduling by offering dynamic capacity planning tools that provide real-time insights into resource availability. Features include:

- Work Center Load Analysis: Visualize how much work is scheduled for each work center over a given time period.

- Utilization Metrics: Track how efficiently work centers are being used and identify idle capacity.

- Prioritization Tools: Flag urgent production orders to ensure they are completed first.

For instance, if your assembly line is overloaded, you can reassign tasks to underutilized resources or adjust schedules to optimize output.

Real-Life Applications of Capacity Planning

Imagine you're running a factory with multiple assembly lines. You discover that one line is consistently finishing ahead of schedule while another is falling behind. Using Business Central's capacity planning tools, you can:

- Reallocate workers from the underutilized line to the overloaded one.

- Adjust routing sequences to distribute tasks more evenly.

- Use Power BI dashboards to monitor capacity across all work centers.

This kind of actionable insight ensures that your factory operates at peak efficiency.

Take Action:

Discover how to streamline work centers and maximize resource efficiency by watching our webinar.