Mastering Manufacturing with Business Central: Understanding Subcontracting

When it comes to modern manufacturing, efficiency often means knowing when to outsource. In Microsoft Dynamics 365 Business Central, subcontracting allows you to do just that—outsource specific production steps to a vendor while still maintaining full control over your inventory and processes. In this first blog of our subcontracting series, we'll explore what subcontracting is, when to use it, and how it fits into your Business Central environment.

What Is Subcontracting in Business Central?

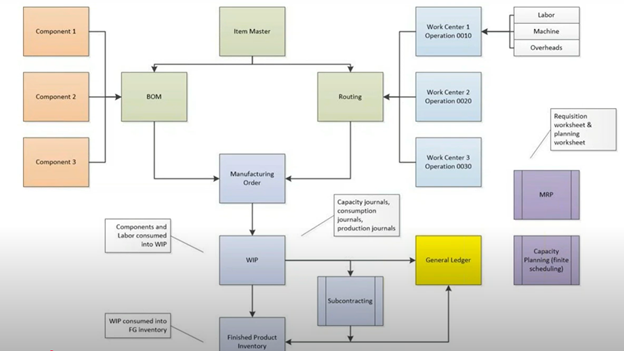

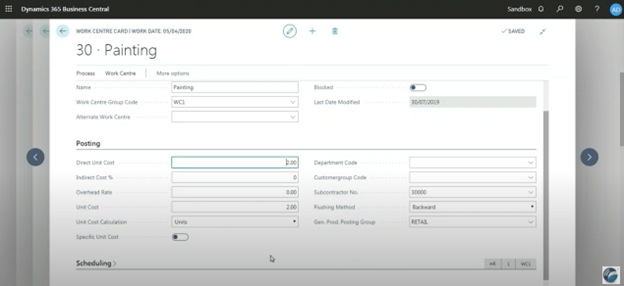

Subcontracting refers to the outsourcing of a specific operation within your production process—such as painting, galvanizing, or coating—to an external vendor. This step is integrated directly into your production routing, and the vendor performs a service on your materials without taking ownership of them.

Business Central makes this easy by distinguishing between internal work centres (your own facilities) and outsourced work centres (vendor operations). This means you can define where each routing step takes place and automatically generate the corresponding purchase orders for the vendor's service.

When Should You Use Subcontracting?

Subcontracting is ideal when:

- Your facility lacks the capacity for a specific process.

- A specialized service (e.g., powder coating or anodizing) is better handled by a third party.

- You need to manage seasonal or overflow demand.

There are three common subcontracting scenarios:

- Vendor provides only the service.

Example: You send parts to a vendor to be painted. They paint and return them you pay for the service. - You provide components to the vendor.

Example: You ship additional parts to the vendor alongside the main item so they can complete the outsourced step. - Vendor provides parts and the service.

Example: The vendor performs the operation and uses their own materials in the process. You pay for both.

Real-World Examples

"Let's say you're a metal manufacturer. You produce parts in-house but send them to a subcontractor for painting. You're not purchasing the parts from them just the painting service. And you still own those parts."

This approach is common in industries where specialized finishing is required, but managing it manually can lead to inaccuracies, missed costs, or delays. Business Central solves this with its subcontracting worksheet, which tracks production status and ensures that you only send items out once they're ready.

Why Subcontracting Matters

If you're managing production with a mix of internal and vendor processes, failing to properly record those outsourced steps can skew costs, delay production, and reduce visibility. Business Central ensures:

- Accurate costing: Each service fee from a vendor is tied to your production order.

- Inventory ownership: Even when parts are offsite, they remain in your inventory.

- Process automation: With proper setup, purchase orders are automatically generated for subcontracting steps.

What's Next?

Now that you understand the foundational role of subcontracting in Business Central, our next blog will walk you through the setup process including how to configure routing, create outsourced work centres, and ensure correct costing.

Watch the full video: Microsoft Dynamics 365 Business Central Manufacturing Series Part VI: Subcontracting

Contact WebSan Solutions to explore how subcontracting can support your unique manufacturing needs.